When it comes to coating things are slowing down. Building a boat from aluminum has a big advantage over building with wood: curing time is about 10 seconds 😁 instead of 48 hours (with our temperatures). This changes with the coating of the boat.

I used a high quality 2 component coating which needs a primer for aluminum. Apart from the curing time I have to say that this is fabulous material. It sticks, it smooths and it is tough!

As I am not a fan of the high glossy coating (it seems so plastic-ish) I choose the satin gloss variety. And I think this is even more than glossy enough.

I immediately saw that the paint job would require a difficult decission from me: Coating the boat revealed several imperfections. And after cleaning - grinding - filling - coating again it revealed smaller imperfections and so on. And yes on a certain moment I had to decide when enough is enough For a perfectionist that is a big task 😨. So I tried some scenario's which all were helpfull in their own way:

- Have a look at the boat from a bigger distance than 10 cm's

- Call a friend: "... it is important to see that it is hand made ..."

- Consult my wife: "Are professional built boats this perfect..." [?]

|

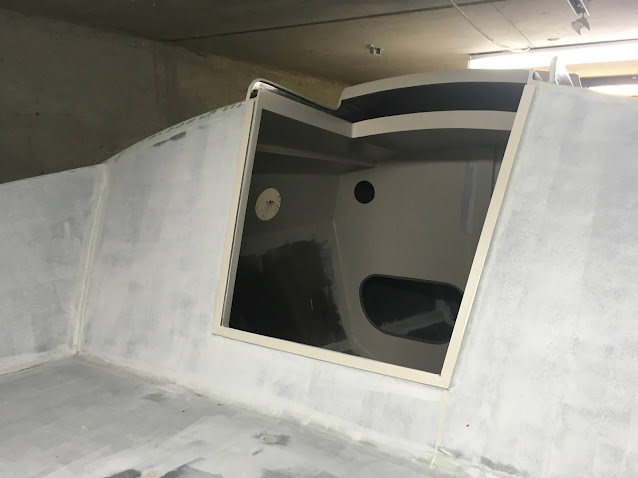

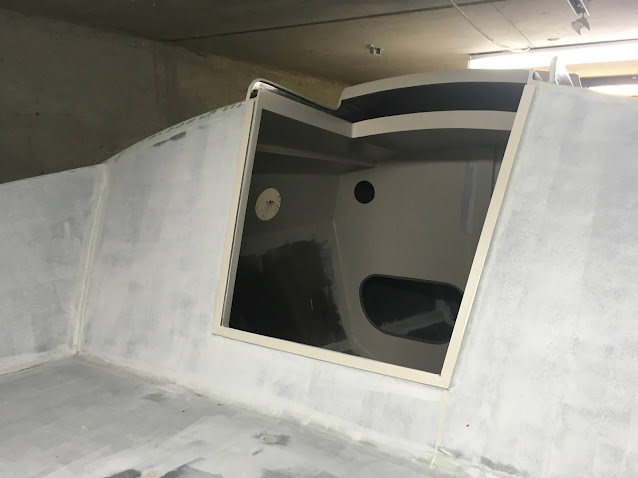

cockpit in the primer (hatches from China...) |

|

| Companion Way Hatch |

And now for the rub rails. I had an idea for these right from the start. I saw a nice product that was made of PVC. It even came in a teak color that can be sanded to mimick wood veins. I only was not sure wether it would show to "gross". Well decide for yourself...

|

Here you can see the T-(mounting) rail (port, right side picture)

|